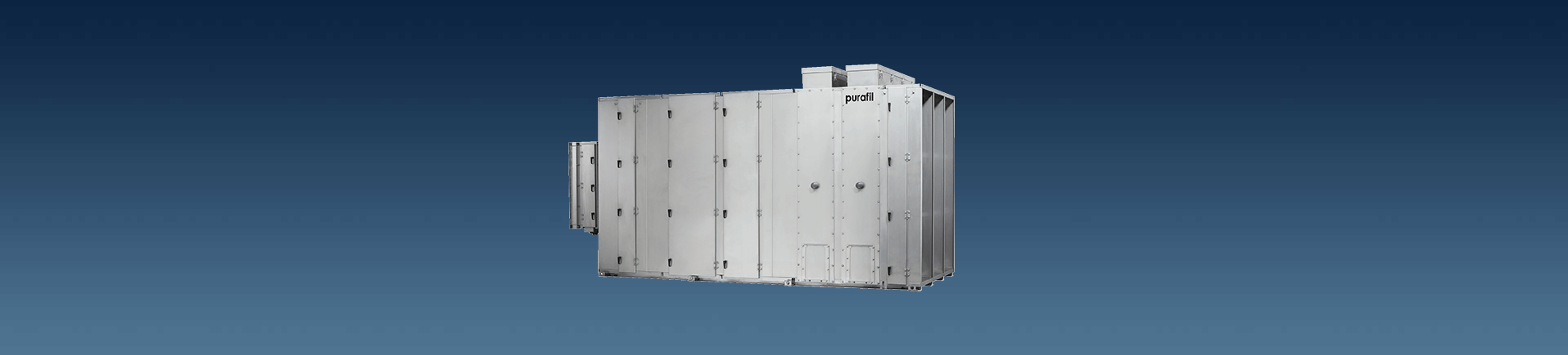

Deep Bed Scrubber

Standard Features

• 3003 H14 aluminum construction

• Pre and Final filters (30% efficient and 90%respectively per ASHRAE standard 52-76)

• Up to three different dry-scrubbing media manufactured by Purafil, Inc.

• Mill and chemical duty motor and blower

• 1.0 IWG (249 Pa) external static pressure

Optional Extras

• Stainless steel construction

• Double Wall construction

• OnGuard® Smart for clean air verification

• Explosion proof motor

• Rainlouver with birdscreen

• Redundant blower, motor, and back draft dampers

• Additional external static

• Pre and final filter gages with housing

• UL listed for hazardous and non-hazardous environment