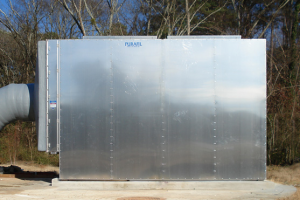

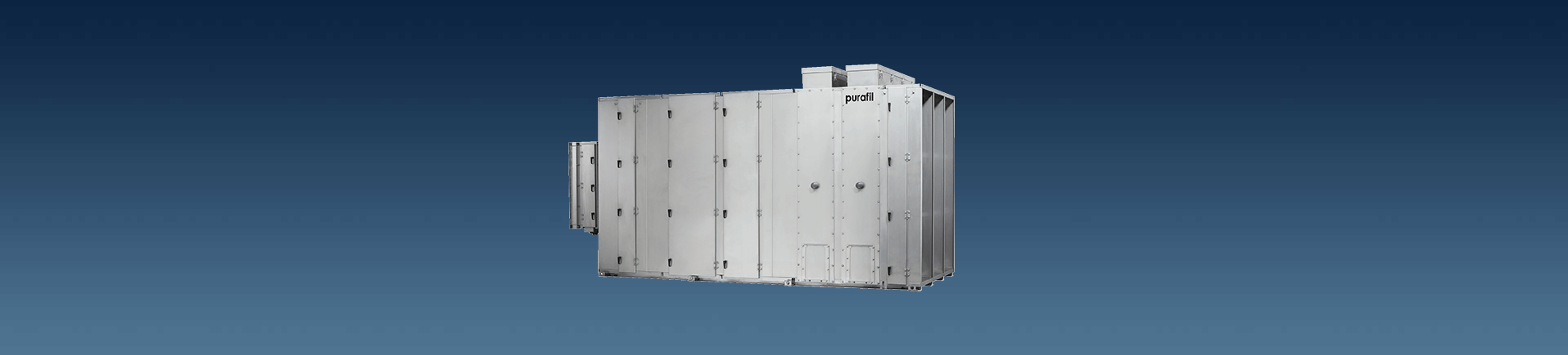

Parallel Bed Scrubber

Standard Features

• 3003 H14 aluminum construction

• Stainless steel hatches and hinges

• Mist eliminator/prefilter

• Up to four, 12-inch-deep (308 mm), parallel vertical media beds (two on each side)

• Externally mounted, draw-through blower system design

• Top access media fill chutes

• 1.0 IWG (249 Pa) external static pressure

Optional Extras

• Double Wall construction

• Air measuring station, CFM gage, and housing (shipping separately for field installation)

• Maintains superior performance in climates with fluctuating temperature and relative humidity

• Lower operating horsepower and pressure drop than activated carbon-only systems

• Sample ports located on side of unit or lid

• Vacuum ports located on side of beds

• Passive applications